Screen printing

Service

In addition to classic dispensing technology, screen printing is another well-known method for applying liquid thermal interface materials (TIMs).

While gap filler liquids are primarily processed with dispensing technology, screen printing is particularly suitable for processing thermal conductive pastes or phase change materials (PCM).

Customer service: Screen printing

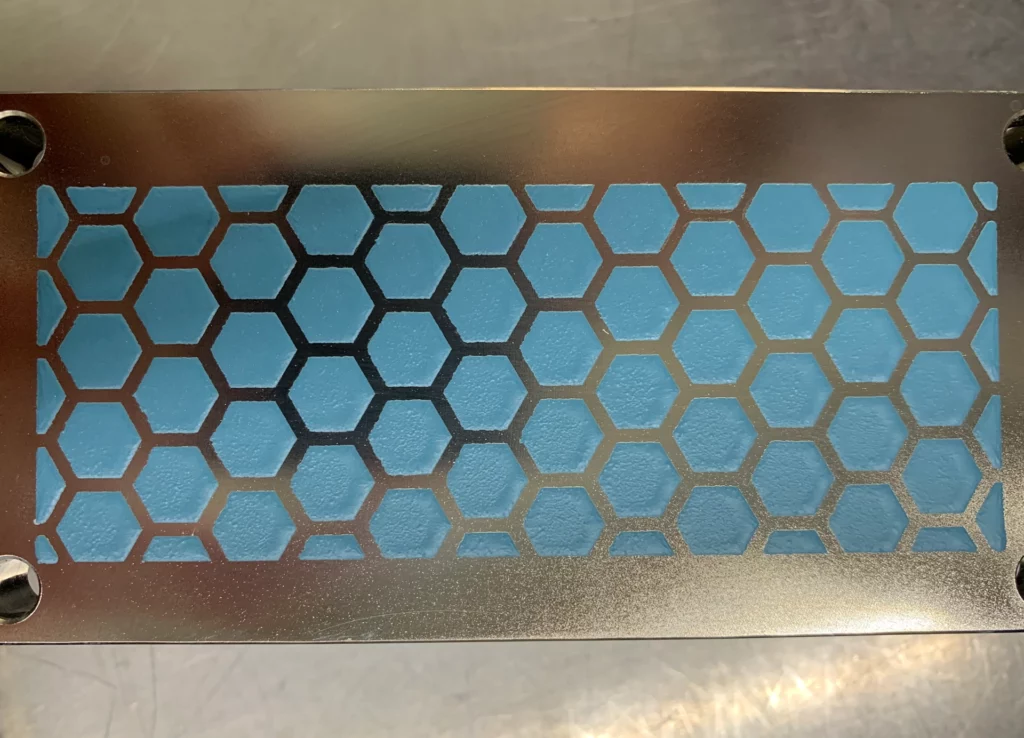

KERAFOL® also offers a screen printing service for the precise application of thermal pastes or PCM materials.

With PCMs, the materials are heated to achieve a certain flow behavior and then applied with an individual screen to ensure the desired final thickness.

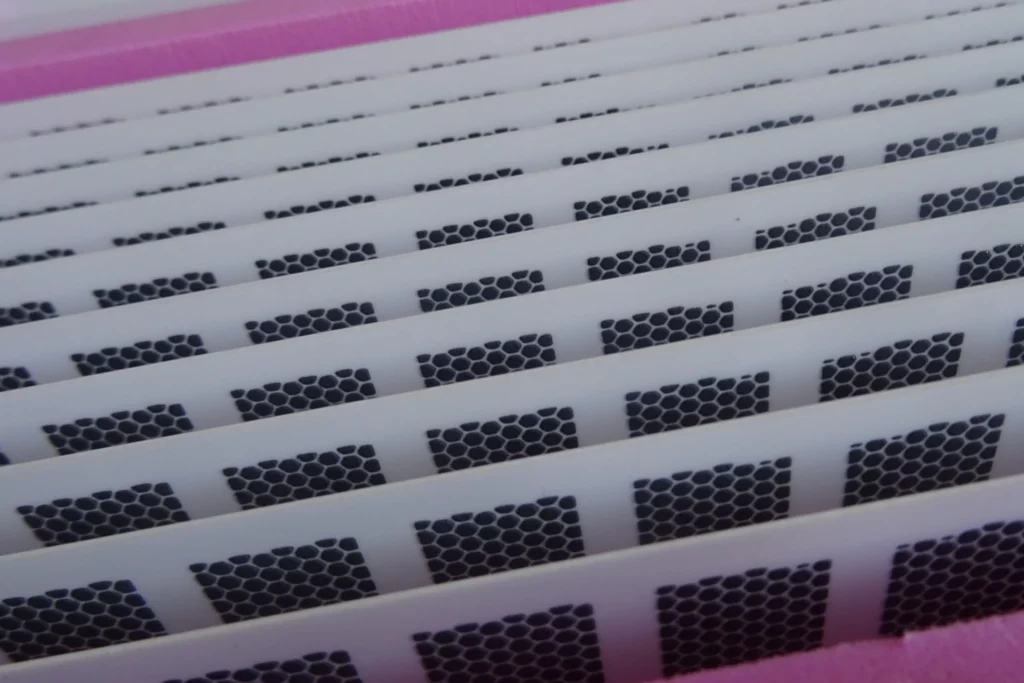

For thermal pastes, KERAFOL® is also able to apply the material to both sides of the end product using a special screen printing process.

Possible applications include the covering of electronic components such as thyristors or the bonding of semiconductors to ceramic or metal plates.

In terms of specification, KERAFOL® can customize the material quantity/unit, size and shape of the screens.

The final quality control is extremely precise, with the entire shape of the applied material being automatically measured, checked and recorded according to the agreed specification.

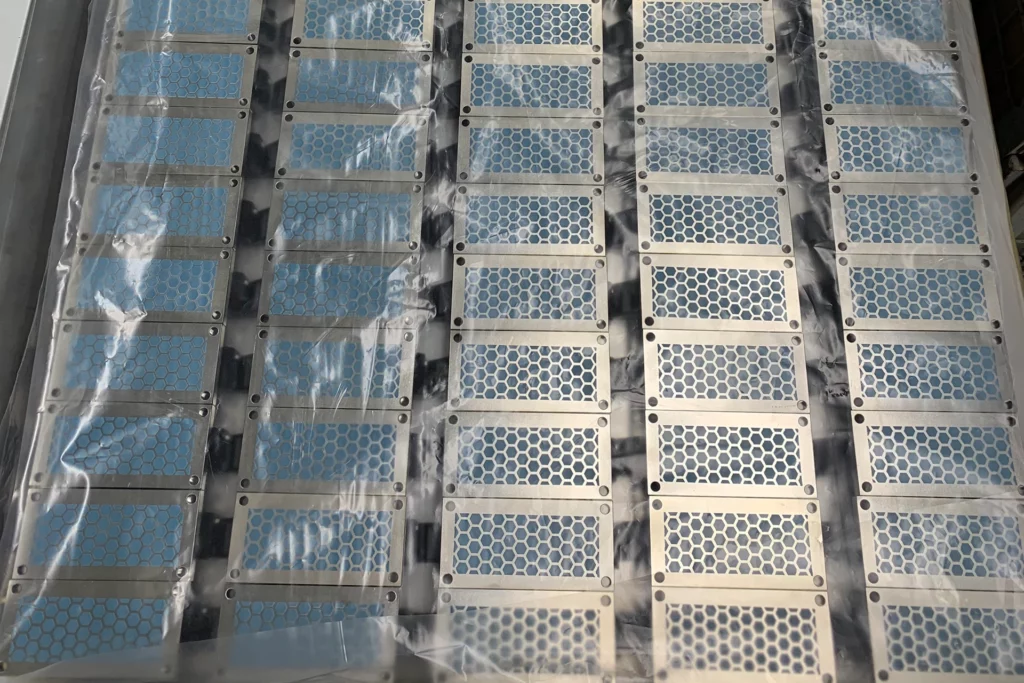

KERAFOL® also takes responsibility for the packaging design and an appropriate logistical process to avoid contamination or smudging.

The service extends from prototypes to series production.

Test preparation

Screen printing service from Kerafol®

- Kick-off meeting with project presentation

- Advance shipment of the required parts (setting up the equipment)

- Specification of cycle times / layer thickness/etc.

- Dimensions / dosing quantities (if required)

- Specification of special requirements (if required)