Dispensing technology

Service

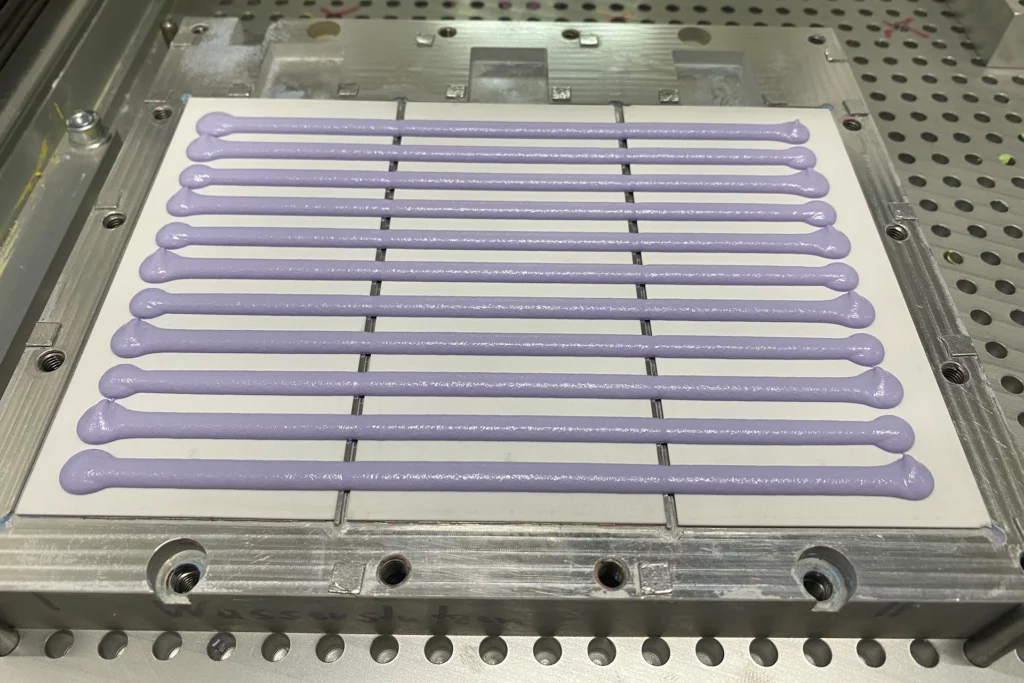

In addition to the development and production of thermally conductive gap filler liquids (GFL), KERAFOL® is also intensively involved in the corresponding processing technology. The dispensing technology required for this is therefore of great importance and is already taken into account in the product development phase. This technology is a decisive criterion for product release. Thanks to the large number of gap fillers with different properties such as viscosity, thixotropy, flow behavior or density, these can be tested in advance and used reliably in the case of customer dosages.

Video: Order GFL 3030

Customer service: Dosing 2K products

KERAFOL® has a professional CNC-controlled dispensing system that is available for trials under the guidance of an expert. Here, customer-specific test setups can be dispensed and assembled directly on site, ideal for test setups in the sampling phase. In this way, initial parameters of the series process (cycle times, dosing quantity, etc.) can be determined. The main advantage of such a service is that an automated process with high repeatability and dispensing accuracy can be simulated, which is not the case with manual test dispensing (human factor). The 2C-GFL for the tests is always fresh and perfectly homogenized, which is also often not the case with sample cartridges (especially if stored incorrectly).

Test preparation

Dispensing technology from Kerafol®

- Kick-off meeting with project presentation

- Advance shipment of the required parts (setting up the equipment)

- Specification of cycle times / layer thickness/etc.

- Dimensions / dosing quantities (if required)

- Specification of special requirements (if required)