Industry

Industry / Markets

HVAC

The HVAC (heating, ventilation & air conditioning) sector includes some very established technology, but also a highly innovative field of application.

The best example of this is heat pumps; the technical functionality is not new, but the demands on the assembly in terms of durability, reliability and efficiency have steadily increased in recent years.

Solutions

for HVAC

Control and automation technology

The field of control and automation technology was one of the first applications for the use of thermal interface materials and has developed steadily over the last few decades.

The demands on automation technology are becoming increasingly diverse, from decentralized energy supplies to the integration of various modules in the field of sensor technology and robotics.

In this industry in particular, the focus is on the development and integration of high-performance electronics, for which various semiconductors such as IGBTs or MOSFETs are used in the various packages (TOs).

Solutions

for control and automation technology

Data transmission - and storage / connectivity

We are currently living in the fourth industrial revolution, which is based on the concept of digitalization and includes automation, artificial intelligence (AI) technologies, networked devices, data analysis, digital transformation and much more.

The fast and secure transmission and storage of data are essential for the use and further development of the above-mentioned areas and a basic requirement.

The 5G standard was introduced for faster data transmission; the frequencies are significantly higher compared to the LTE range and are currently up to 40 GHz, with an expansion to up to 80 GHz planned.

The higher frequencies and data rates combined with ever smaller distances between the individual antennas (transmitter/receiver units) result in increased temperatures of the electronic components and possible electromagnetic interference between the individual components.

This poses new challenges in terms of heat generation and electromagnetic interference in 5G mobile radio towers, cloud servers or storage systems, for example.

The new conditions and technical requirements also have an impact on the design of many components in the transport sector.

Autonomous driving in particular is only possible with a large number of sensors, and radar sensors for distance detection also operate in a very high frequency range.

Materials from the KERABSORB product range serve as thermal interfaces between the electronics and heat sink/housing and can also absorb high levels of electromagnetic radiation at frequencies of up to 80 Ghz.

This paves the way for efficient, powerful and reliable infrastructure systems.

Solutions

for data transmission - and storage / connectivity

LED

Switching from incandescent lamps to LEDs is an important part of reducing energy consumption in the lighting sector.

The thermal management of LEDs is particularly important in terms of their sustainability.

This is due to the fact that individual LEDs and often the entire lighting unit cannot be replaced in the event of a failure.

This means that if the lighting unit fails, the entire assembly must be disposed of.

Even though LEDs are an efficient lighting solution, the energy density in a very small area is very high.

This makes it necessary to dissipate the heat generated locally.

In the event of “hot spots”, graphite foils, for example, can help to distribute the heat across the surface and dissipate it to the surroundings, acting as a “heat spreader”.

Solutions

for LED

Military & Aerospace

The number of electronic applications in the military and aerospace sectors has grown steadily in recent years.

Electrification is also progressing here – drones, energy storage, control systems and equipment in the field of communication and data transfer have long since ceased to be used only in the industrial sector.

Both the military and aerospace follow a similar pattern with regard to the use of electronic assemblies.

The reliability of the components installed in them is clearly in the foreground.

This requires lengthy and extensive functional and application-related (field) tests by the customer as well as the highest demands on quality and the supplier’s quality-relevant processes.

Applications in the military and aerospace sectors demand the highest reliability from the components used.

We manufacture ceramic substrates for sensors suitable for high temperatures, heat and radiation-resistant plates made of zirconium oxide and aluminum oxide as well as ultra-thin and therefore flexible ceramic components for all applications.

Solutions

for Military & Aerospace

Ceramic industry

Ceramic Tapes & Substrates

We are also working more and more with sensitive materials that require extreme purity.

Even traces of impurities in the process can weaken or completely nullify the effectiveness of a fuel cell or battery membrane, for example.

To avoid this, we offer flat components based on zirconium oxide to protect your surfaces exposed to raw materials from abrasion.

Filter ceramic

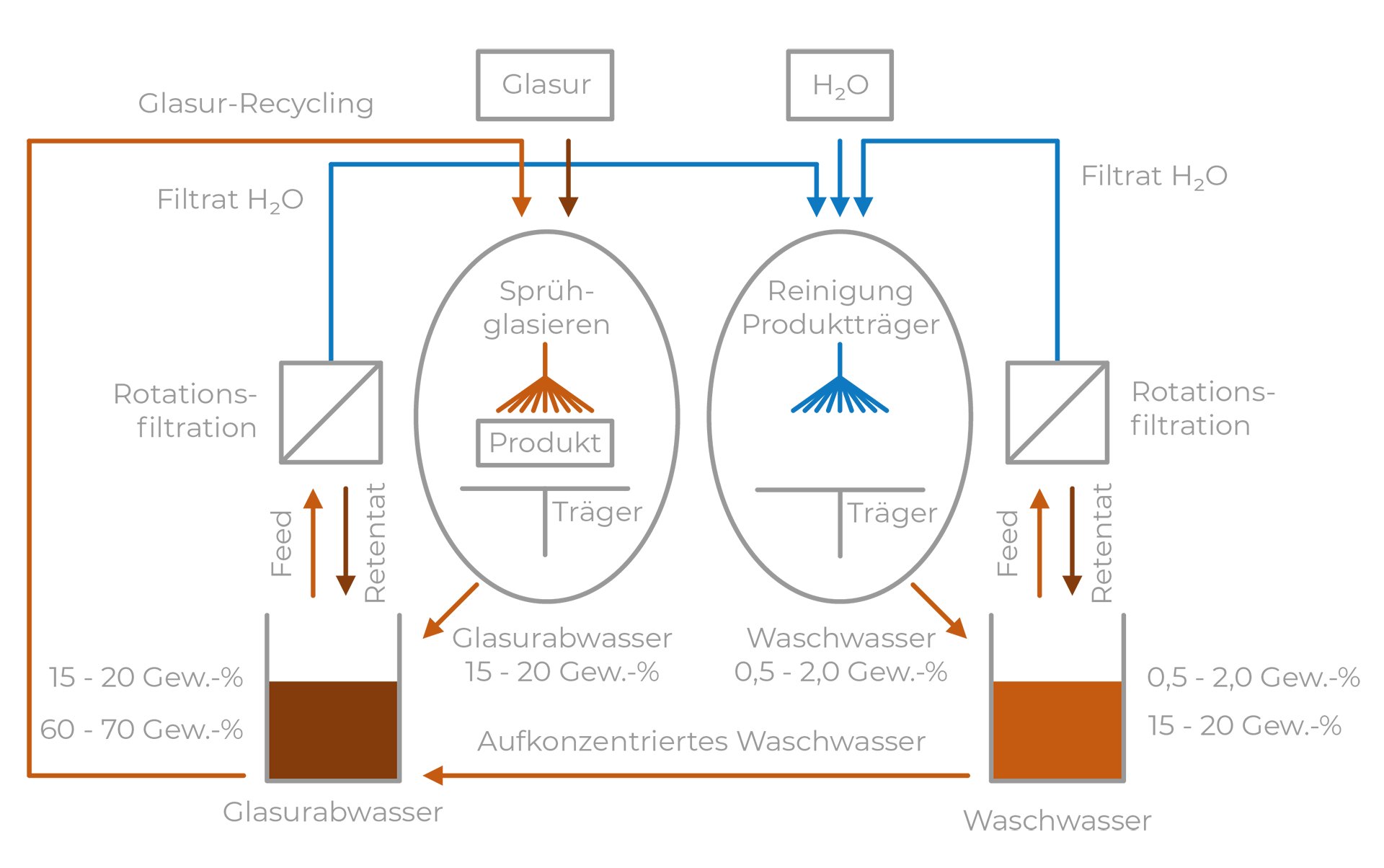

In the ceramics industry, various ceramic suspensions containing valuable raw materials are produced as waste water.

These can be, for example, residues from slips or waste water from spray glazing (loss due to overspray, washing of product carriers).

For both economic and ecological reasons, it is of great interest to recover the raw materials from this waste water or to concentrate them so that they can be directly reused in production.

Keramische Industrie

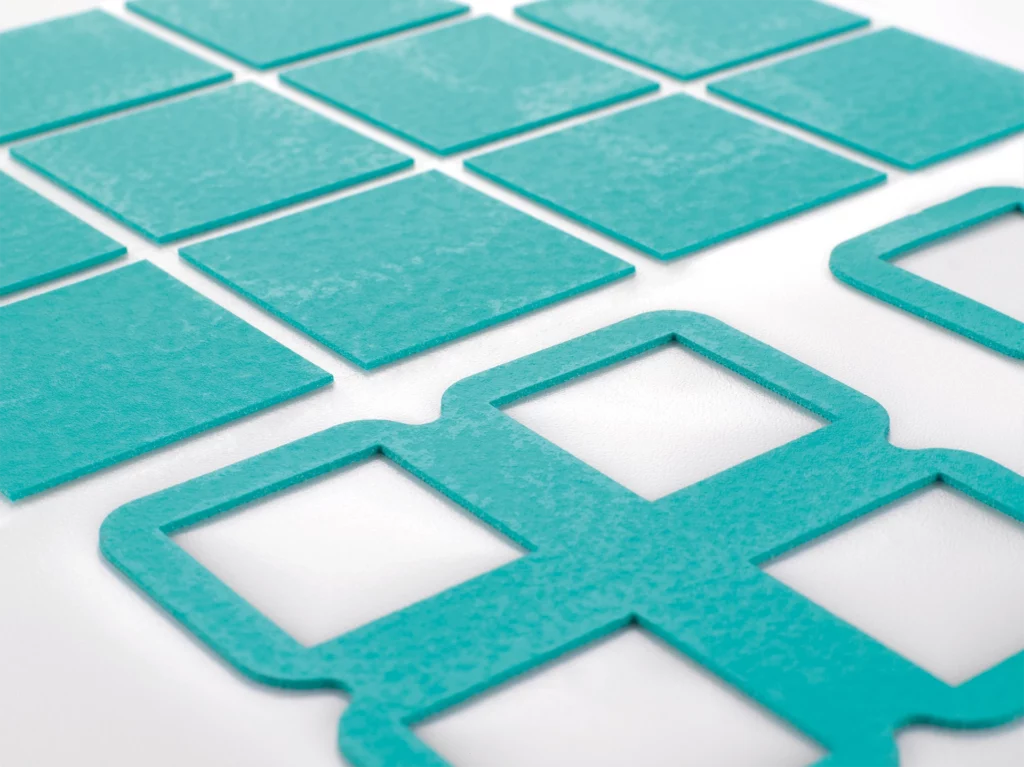

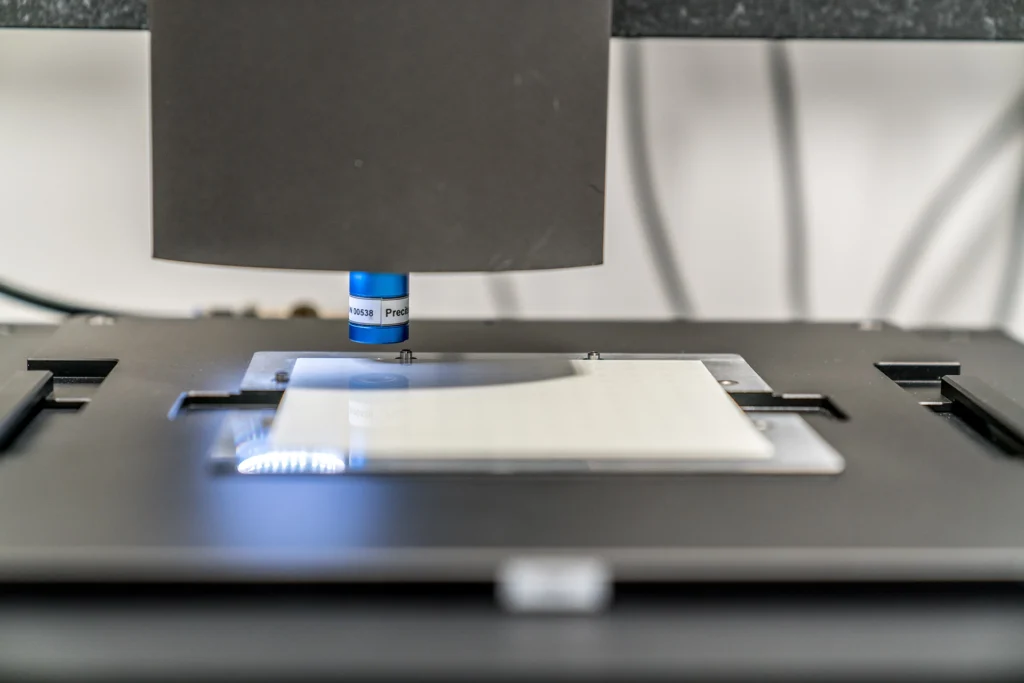

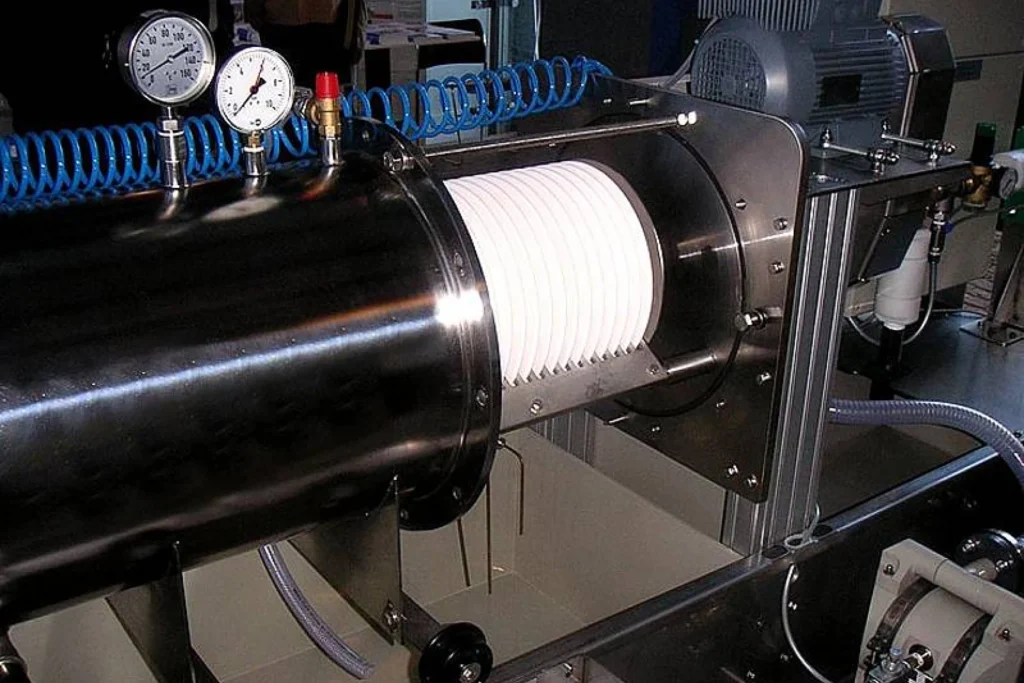

An excellent option for this is Dynamic Cross Flow Filtration with ceramic filter disks from KERAFOL®.

This process allows the suspensions to be concentrated to a solids content of over 60 wt.%. The water produced as filtrate can also be reused directly in production. This results in the principle of a closed cycle.

Solutions

for the ceramics industry

Wear protection

Sintering technology

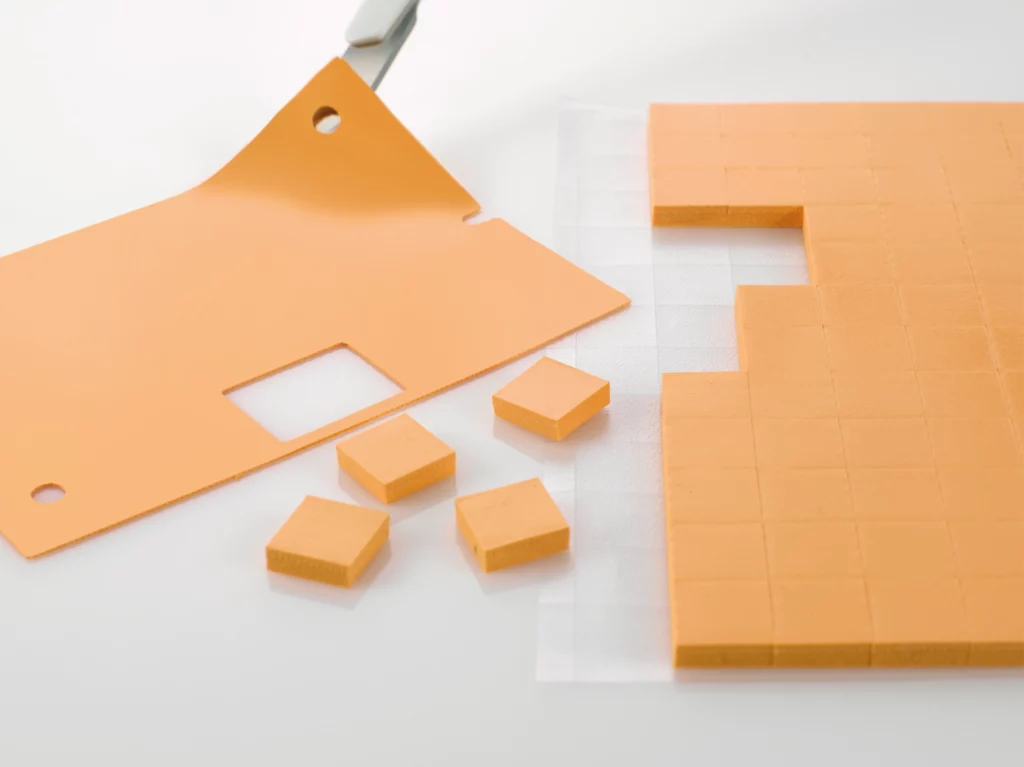

Many components that used to be produced using the time-consuming process of metal casting/ceramic production and subsequent material processing such as turning, drilling, grinding, etc. are now manufactured using metal injection molding and ceramic injection molding, or MIM/CIM for short.

With this process, it is possible to produce large series quantities in a short time with outstanding quality.

The variety of products includes furniture fittings, jewelry, weapon parts, components for cars and medical technology, to name but a few.

The materials are injection-molded in a similar way to plastics, whereby the plastic, the so-called binder, must be removed from the component in order to obtain the desired metallic material properties for the end application.

This is achieved by chemically and/or thermally treating the semi-finished products by subjecting them to a debinding process followed by a sintering process of up to 1400°C, depending on their composition.

Video: Rotary fumigation

Advantages

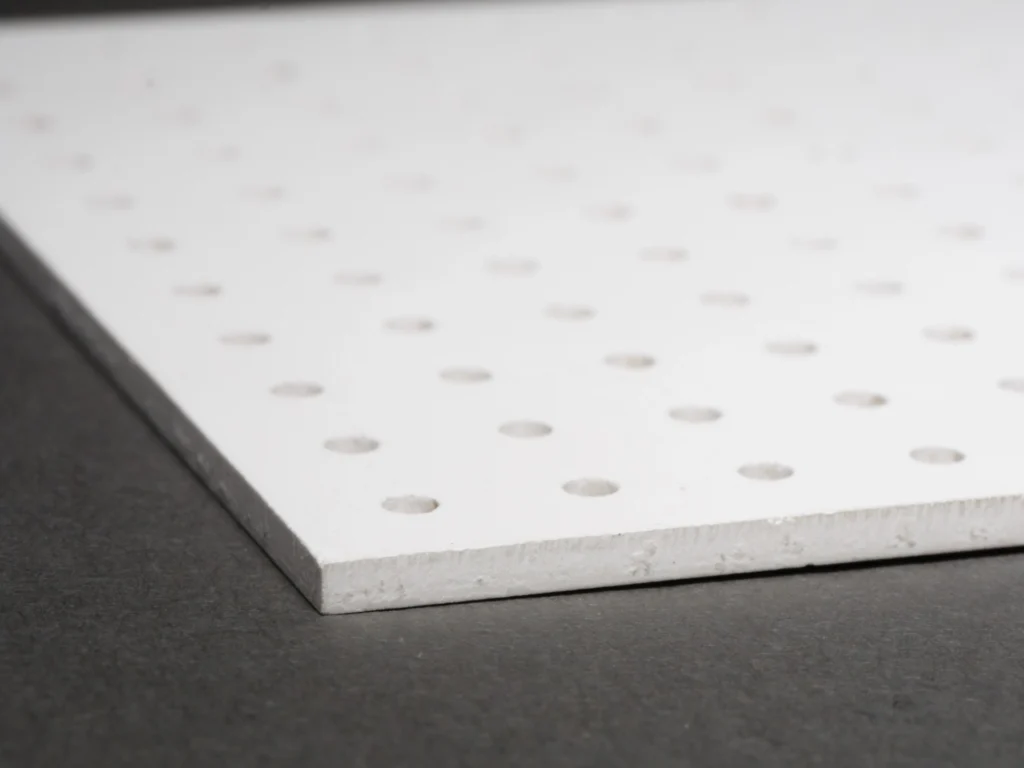

- Dust and particle-free surface

- Homogeneous pore distribution

- Good mechanical strength despite high porosity

- Material can be cut with laser or water jet

- Very good flatness and surface finish

- Large customized dimensions of the sintering pads possible

- Gases and liquids can diffuse unhindered through the sintered substrates

Possible applications

- Sintered underlays for metal injection molding (MIM)

- Sintering bases for ceramic or dental ceramic production

- Gas-permeable membranes for sensors

- Porous diaphragm for e.g. electrolytes in battery technology

Food

Ceramic filters are ideal for processing food.

They do not release any ingredients and there are no plasticizers or other substances that are harmful or change the taste.

This enables a wide range of applications for rotary filtration in the food and beverage industry.

The possibility of squeezing the “last drop” out of the retentate becomes clear in beer/yeast recovery or in the filtration of wine lees.

The dairy industry benefits from the separation of bacteria or the fractionation of casein and proteins.

The retentate is also important in the filtration of selected juices (e.g. carrot juice for color extraction) or the production of concentrated tomato paste.

Begasung

For this purpose, the membrane disks are exposed to air or pure oxygen from the inside.

Gas bubbles form on the membrane surface, which are sheared off by the rotation during the formation process.

This results in an extremely fine gas bubble distribution and the oxygen can dissolve very well in the water.

On the other hand, disinfection can be carried out using ozone.

In this case, the process described above is carried out with ozone.