Ceramic Tapes & Substrates

Technical ceramics

Video: Ceramic Tapes & Substrates

Main features

CTS by KERAFOL®

- Excellent high temperature resistance

- Good corrosion resistance

- High mechanical strength

- Low weight

- Low space requirement

- Low heat capacity

- Great hardness

- Very good mechanical abrasion resistance

- Good flexibility of thin ceramic substrates

- Depending on the material, good to very good thermal conductivity

- Very good electrical insulation properties

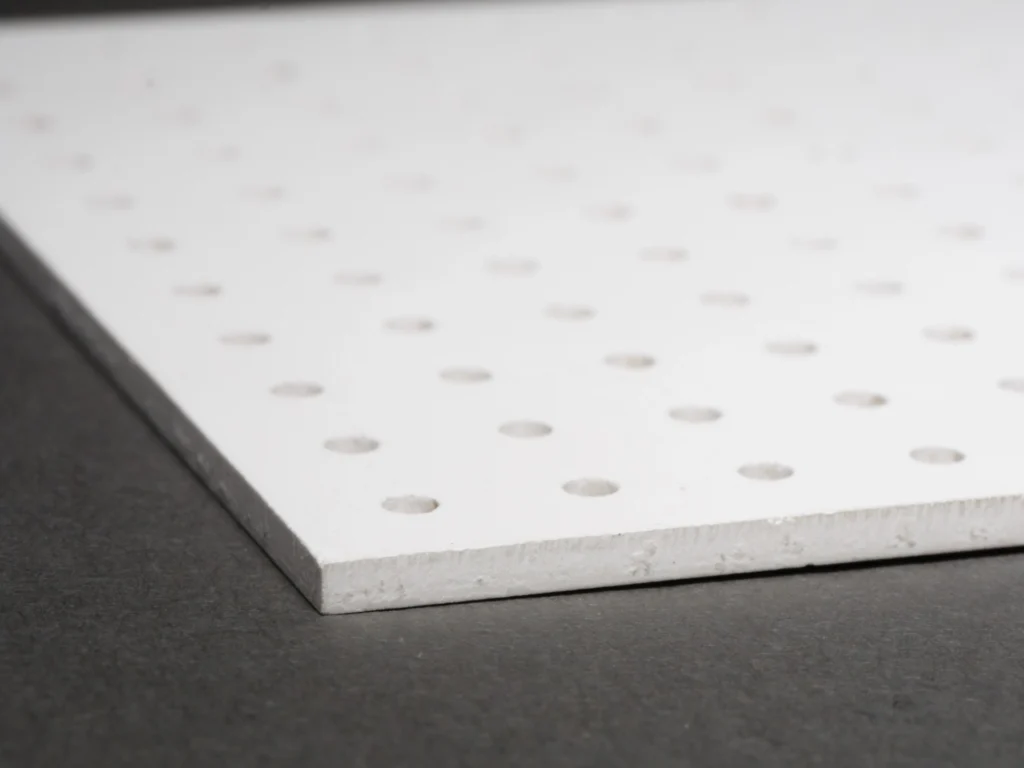

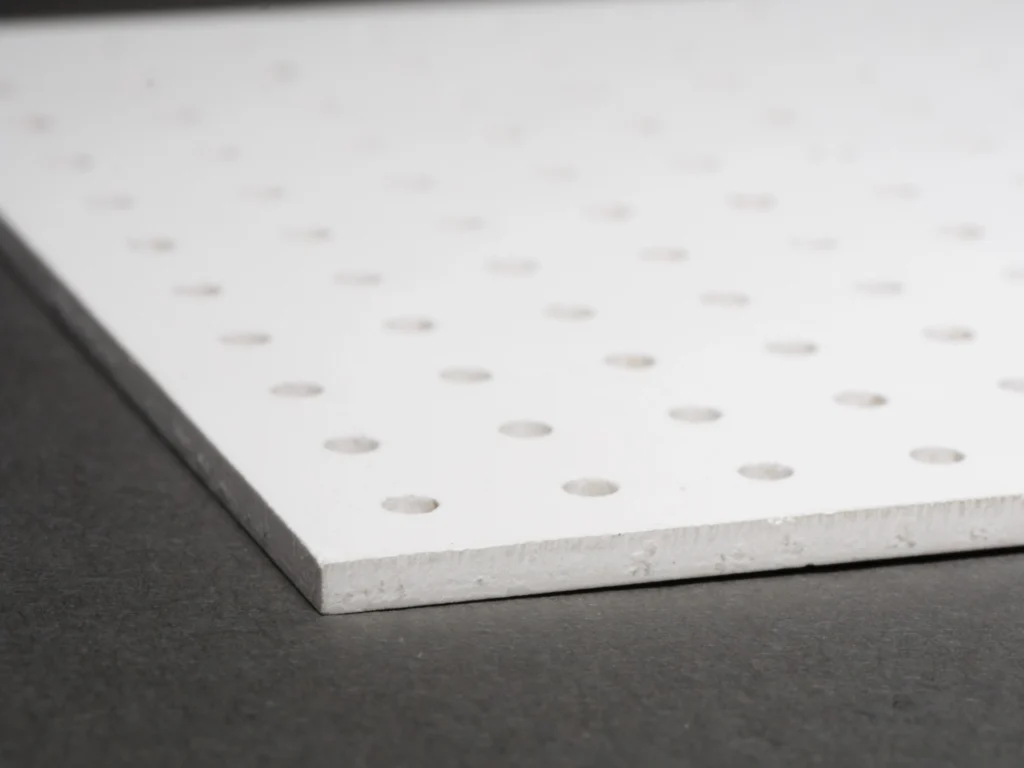

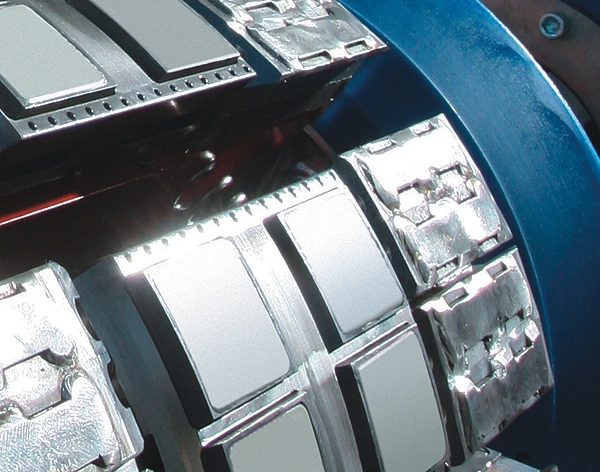

Setter / kiln furniture

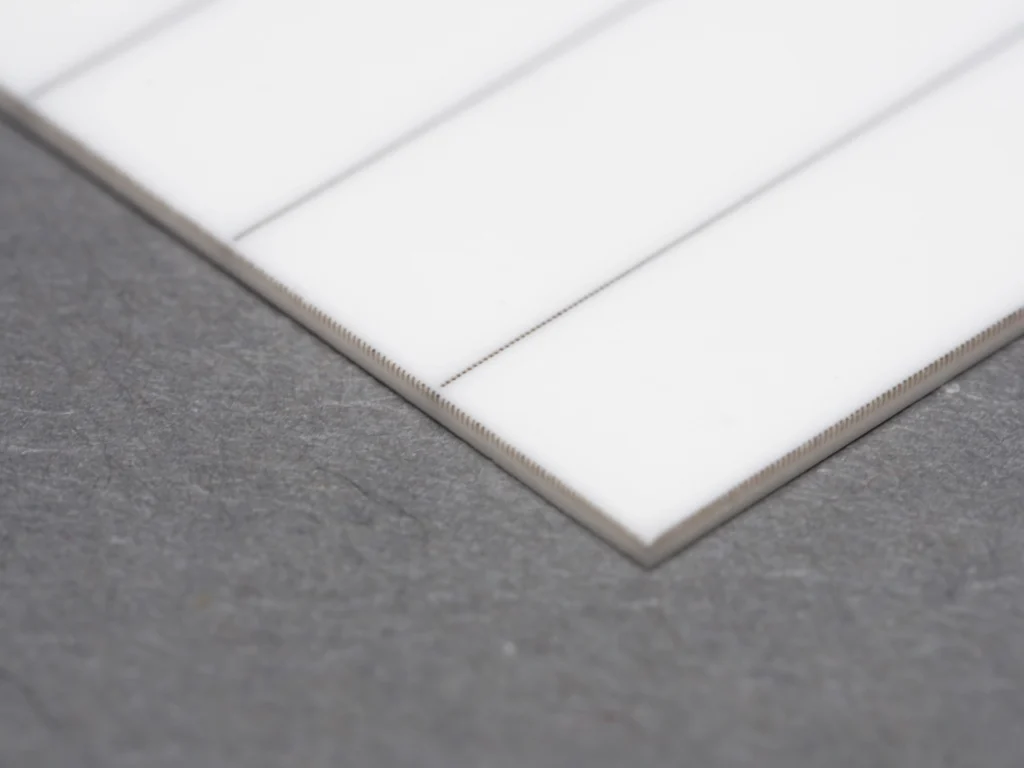

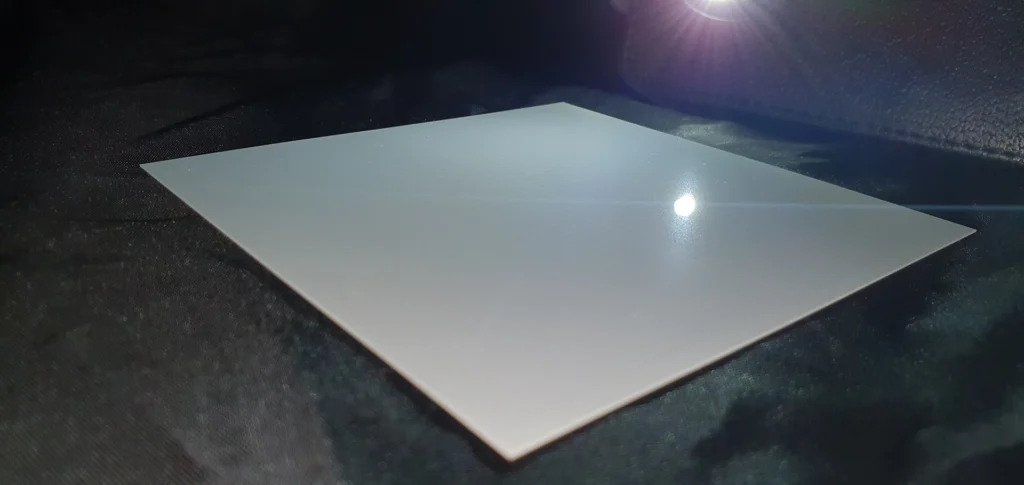

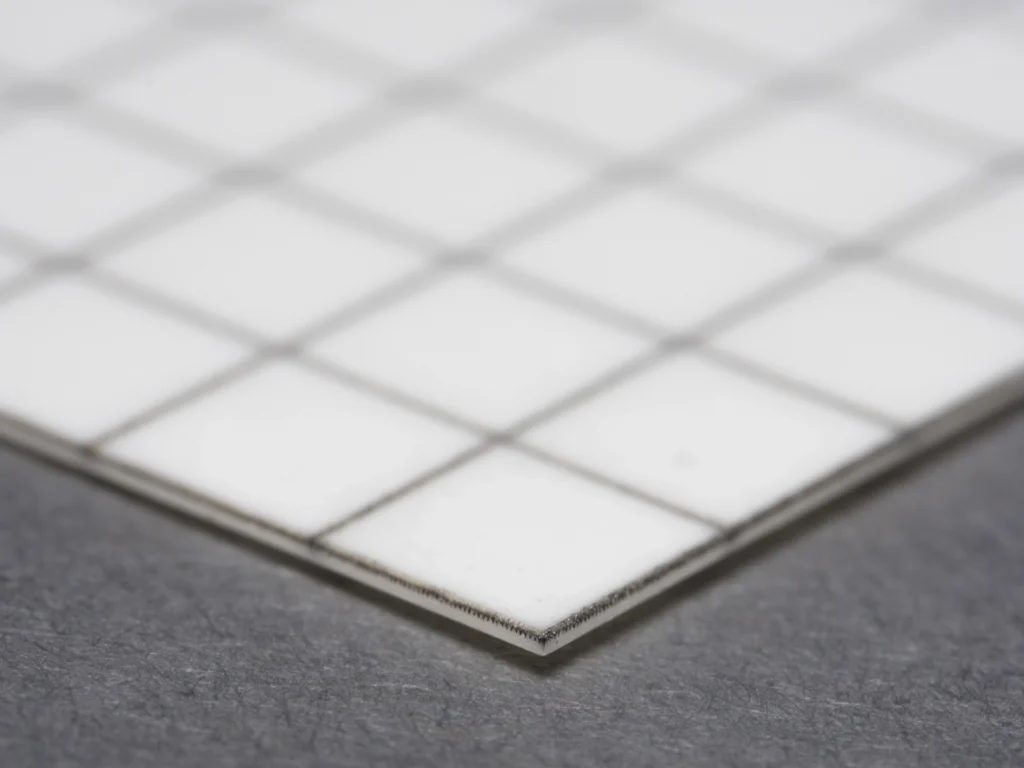

Thin and thick film substrates

Thin-film technology

Conductor tracks that are produced using thin-film technology have layer thicknesses ranging from a few nanometers (monolayer) to several micrometers.

Electronic semiconductor components and special platinum temperature sensors (Pt 100, Pt 1000, etc.) are the most important applications in the field of thin-film technology.

The average thickness of the conductor tracks is approx. 1 µm.

The conductor tracks for thin-film substrates are applied at approx. 1200°C using the PVD process or sputtering.

The substrates for thin-film technology are therefore subject to stringent requirements in terms of the surface quality and grain structure of the ceramic.

Thick film technology

Thick-film technology is used to build electronic components such as sensors or integrated hybrid circuits using LTCC or HTCC technology.

The electrical conductors for thick-film coating technology are applied to the film or substrate material using a screen printing process.

Wear protection ceramics

Contact person

Do you have any questions, requests or suggestions?

How can we help you?

Dipl.-Ing. Franz-Martin Fuchs & Dipl.-Phys. Christian Münch

Business Unit Manger Technical Ceramics

Phone: +49(0) 9645 – 88 430 / +49(0) 9645 – 88 610

E-mail: cts@kerafol.com