Dynamic cross flow filtration

DCFF

Maximum filtration performance with minimum energy input: this can be achieved with Rotation Filtration or Dynamic Cross Flow Filtration (DCFF).

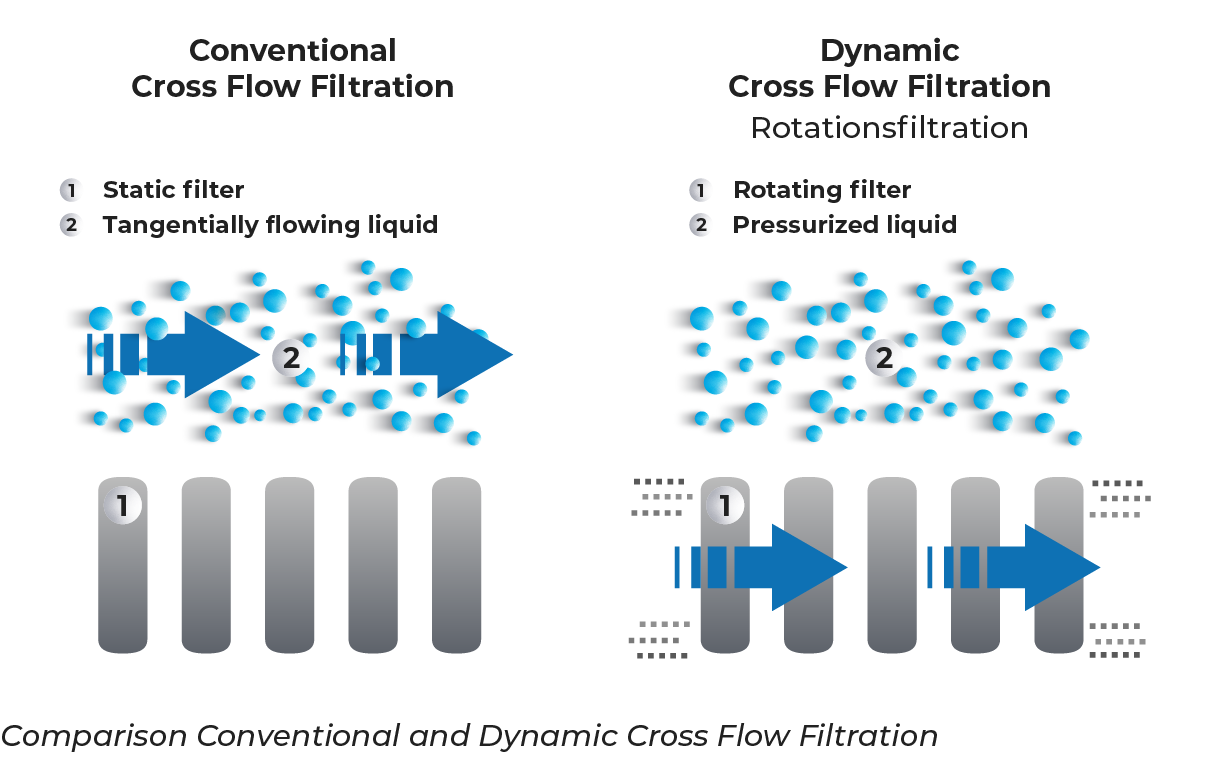

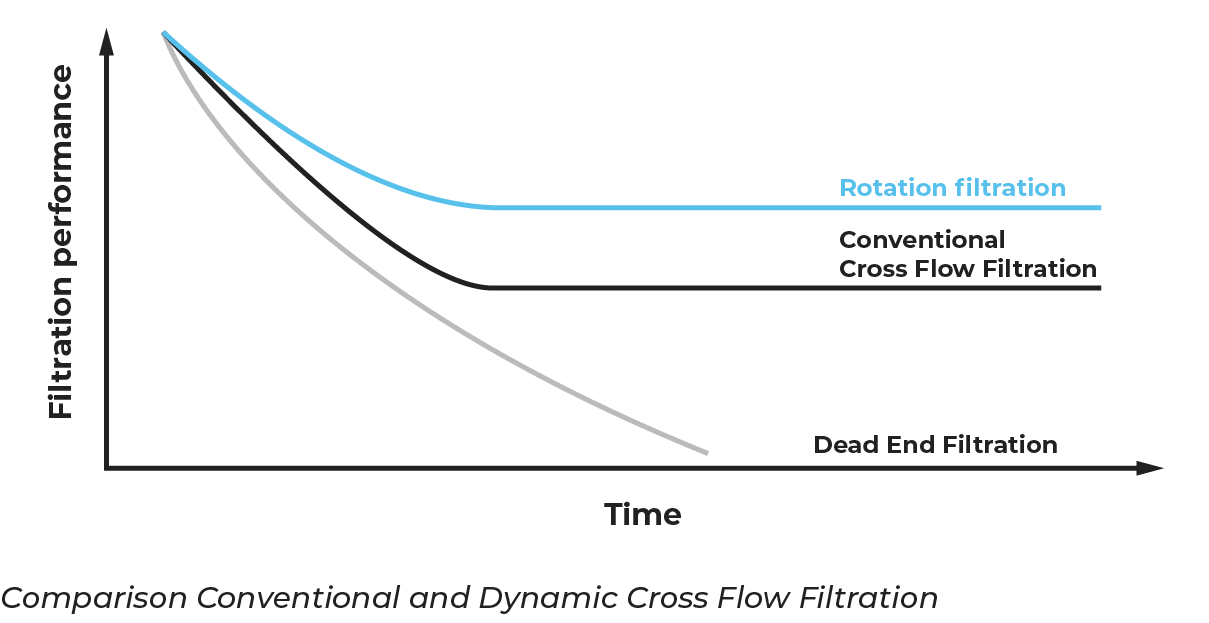

The tangential overflow of the filter surface (crossflow effect) is achieved in this process by rotating the filter disks generated. This significantly reduces energy costs compared to conventional crossflow processes. In the latter, powerful pumps are required to move large volumes of liquid and thus ensure overflow. In addition, moderate transmembrane pressures (typically up to 2.5 bar) are sufficient with the DCFF and there is a uniform pressure over the entire filter surface (independent adjustment of the transmembrane pressure and overflow speed parameters).

Video: DCFF

Another advantage of rotation is the generation of extreme overflow velocities and therefore highly efficient cleaning of the filter surface.

The resulting shear forces efficiently impede the growth of a filter cake and thus achieve a higher filtrate flow.

Rotation filtration is ideal for processing highly viscous liquids or for concentrating high solids contents.

Principle of rotation filtration

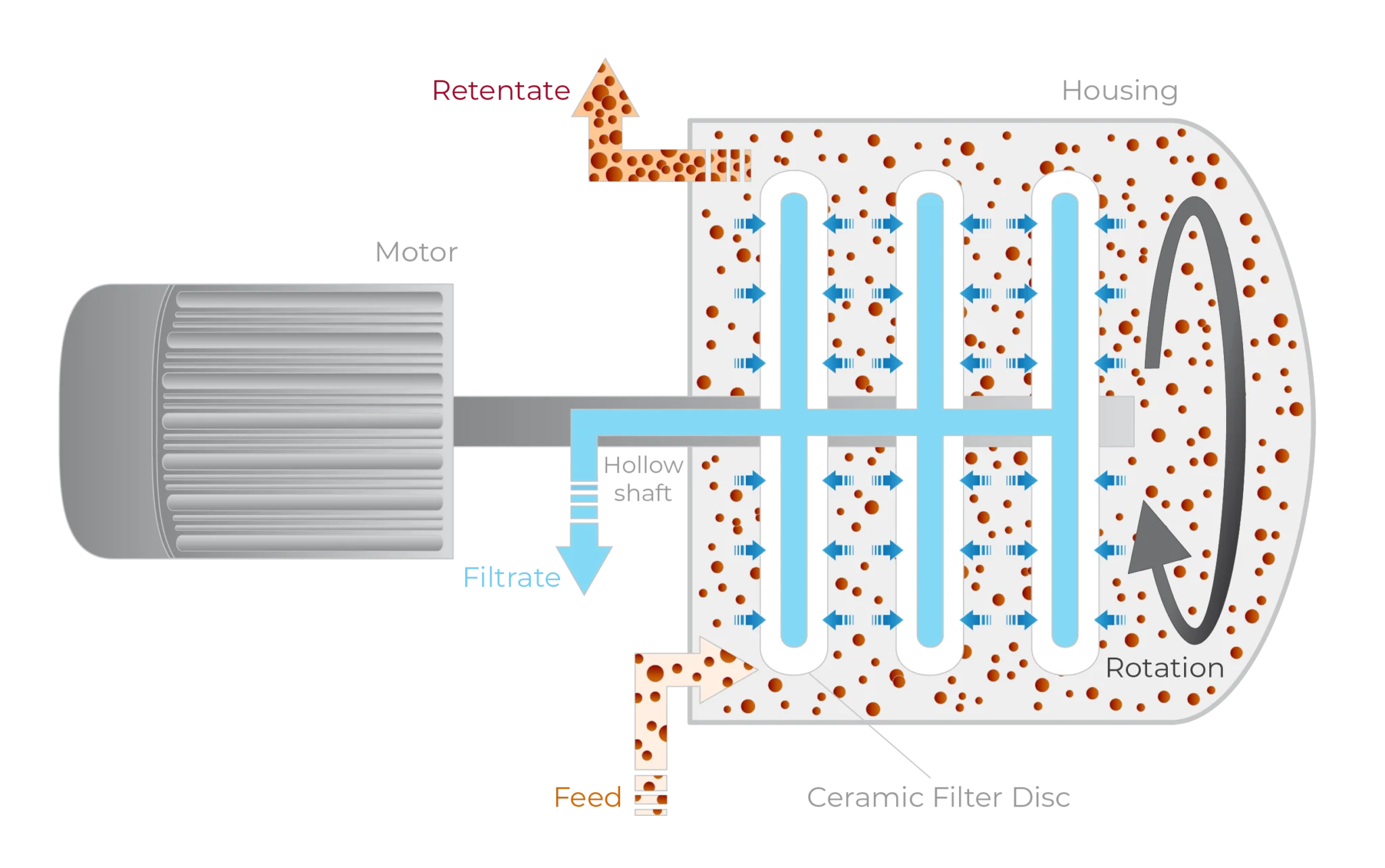

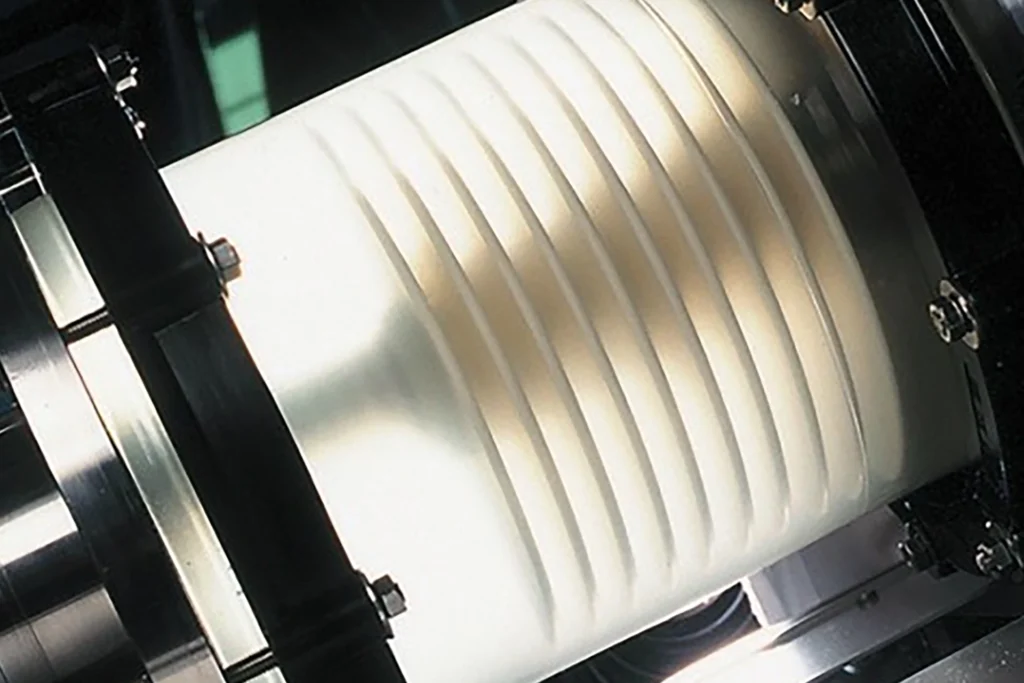

The ceramic filter discs are mounted on one or more hollow shafts that rotate inside a pressure housing.

The discs have drainage channels on the inside.

The transmembrane pressure transports the filtrate from the outside to the inside of the discs.

The filtrate is removed from the system via the channels in the discs and the hollow shaft.

All common types of process control can be realized with the DCFF (single-pass, batch, fed-batch, feed-and-bleed).

374mm, 312mm, 152mm

Main parameters

- Rotation speed (rotating ceramic filter discs)

- Transmembrane pressure TMP (pressure housing)

- Solids content (concentration of liquids due to the discharge of filtrate)

Filter systems

KERAFOL® is an independent manufacturer of ceramic membrane discs.

Our customers include various plant manufacturers worldwide who develop and sell suitable systems for a wide range of applications (waste and process water, digestate treatment, chemical and pharmaceutical industry, food and beverage industry, oil and gas industry, etc.).

We would be happy to put you in contact with these companies.

We are always on the lookout for new plant manufacturers who are enthusiastic about dynamic cross-flow filtration with KERAFOL® filter discs and want to work with us to further establish this filtration process on the market.

We support you in the development of your own system with all our expertise and provide you with the necessary parameters for installing the discs in your systems (sealing, fixing, process parameters).

Not sure whether DCFF is the right process for you? Then take the opportunity and hire one of our test filtration plants.

Case Studies

Processing of ceramic suspensions using Dynamic Crossflow Filtration (DCFF)

Efficient oxygen supply in fish farming

Sustainable Manure and Digestate Treatment through Innovative Filtration Technologies

Ceramic filters offer maximum process reliability

- Stability against chemical and thermal stresses

- Regeneration by backwashing or hot steam sterilization

- High filtration performance and very long service life

We provide you with the necessary parameters for installing the panes in your systems (sealing, fixing, process parameters).

Applications

from Dynamic Cross Flow Filtration

- in environmental technology, e.g. (waste) water treatment, agricultural technology

- in areas of the ceramics industry (glaze preparation, slurry concentration, ...)

- in the food industry (wine, beer, fruit juice, ...)

- in the medical technology and pharmaceutical industry

Contact person

Do you have any questions, requests or suggestions? How can we help you?

Dipl.-Phys. Christian Münch & Dipl.-Ing. Franz-Martin Fuchs

Business Unit Manger Technical Ceramics

Phone: +49(0) 9645 – 88 610 / +49(0) 9645 – 88 430

E-mail: keramik@kerafol.com