Keralpor S

92 % alumina + 8 % zirconia

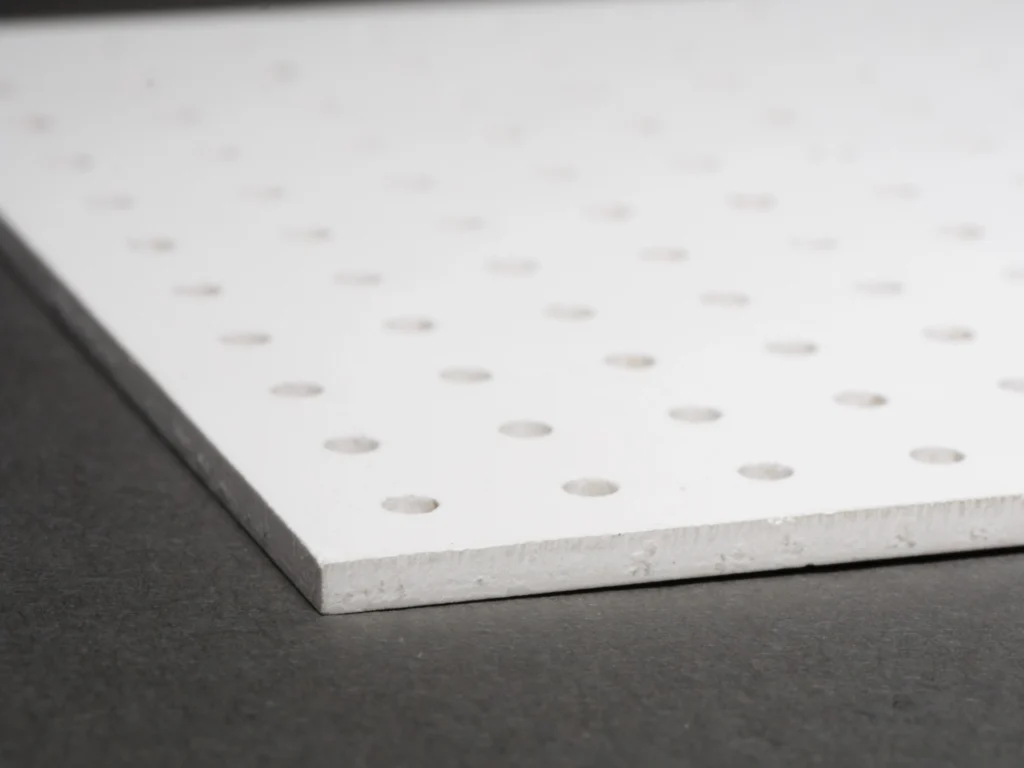

Keralpor S is a setter, that can be used for sintering various of metal injection molding products and materials (MIM).

The advantages of this porous zirconia toughened alumina are its good thermal shock resistance and high mechanical strength. Through the 32 % porous structure, adhesion of the sintered part will be prevented.

Our customers use Keralpor S primarily for debinding and sintering stainless steel products (MIM); it is also used for fast cooling processes in the kiln.

All sizes up to 310 x 310 mm are available in a thickness of 1.6 mm.

Please request your customized dimensions and we will produce your Keralpor S as quickly as possible.

Advantages

from KERALPOR S

- Dust and particle-free surface

- Homogeneous pore distribution

- Good mechanical strength despite to the high porosity

- Water jet or laser cutting possible

- Good thermal shock resistance

- Good planarity and surface quality

- Customized dimensions of the setters are possible

- Gases can freely diffuse through the settermatrix

Applications

Keralpor S

- Setter plate for metal injection molding (MIM)

- Setter plate for ceramic injection molding (CIM)

- Setter plate for high demand of thermal shock resistance