Gap pads

(Softtherm®)

The constantly increasing technical demands on electrical and electronic assemblies lead to major challenges in the area of thermal management.

Due to the miniaturization of components and the higher performance of devices, component temperatures would increase significantly without countermeasures, which can lead to the failure of the entire assembly.

In order to increase the longevity of electronic components, heat must therefore be conducted from the heat source (electronics) to the heat sink (e.g. heat sink).

Thermally conductive and electrically insulating intermediate layer materials, so-called Thermal Interface Materials (TIMs), are used for this purpose.

KERAFOL® has developed effective, uncomplicated and cost-effective solutions in this area with the KERATHERM® and KERAMOLD® product ranges.

One of the best-known product groups are the so-called Gap Pads (SOFTTHERM®).

What are gap pads?

an explanation

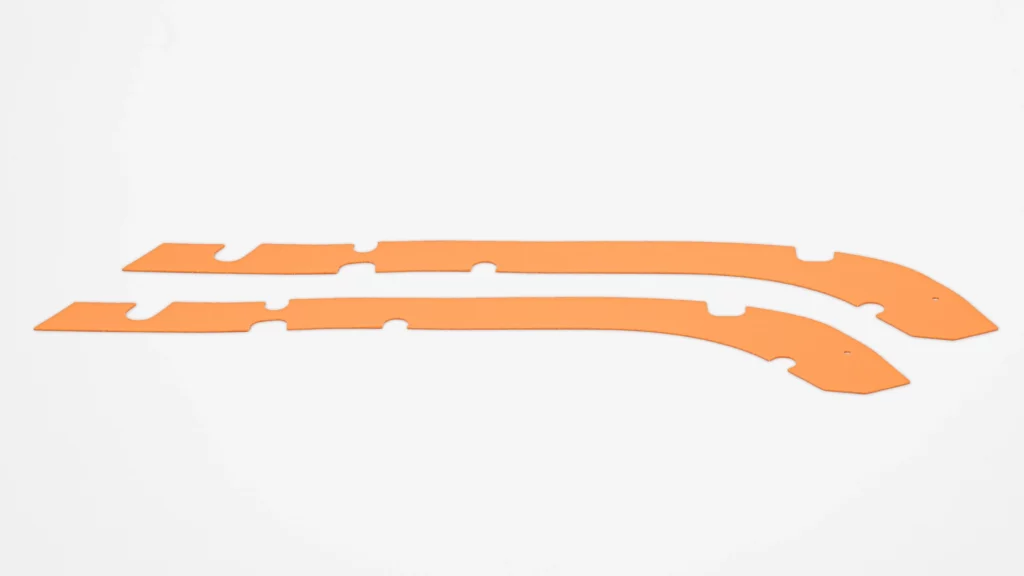

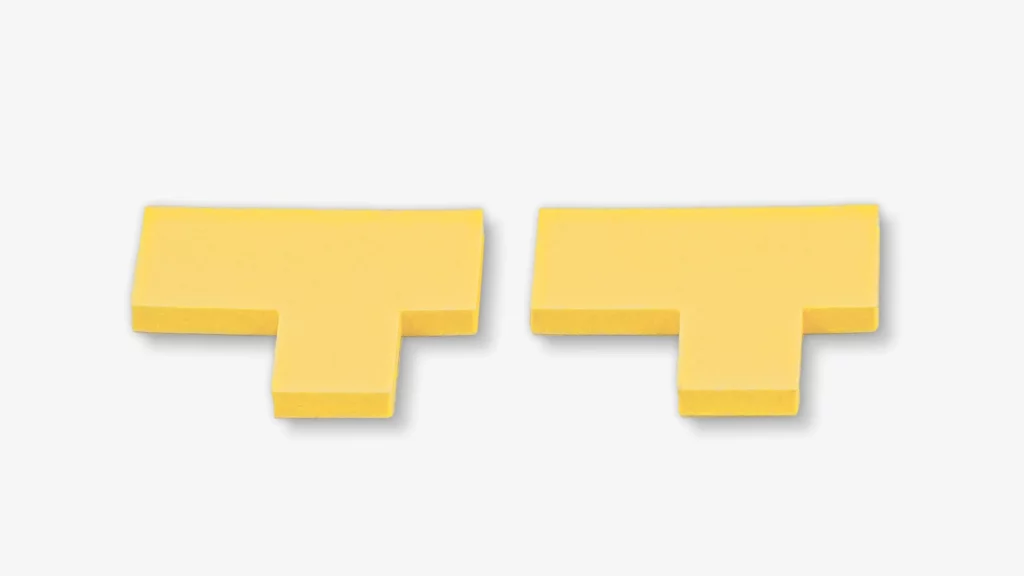

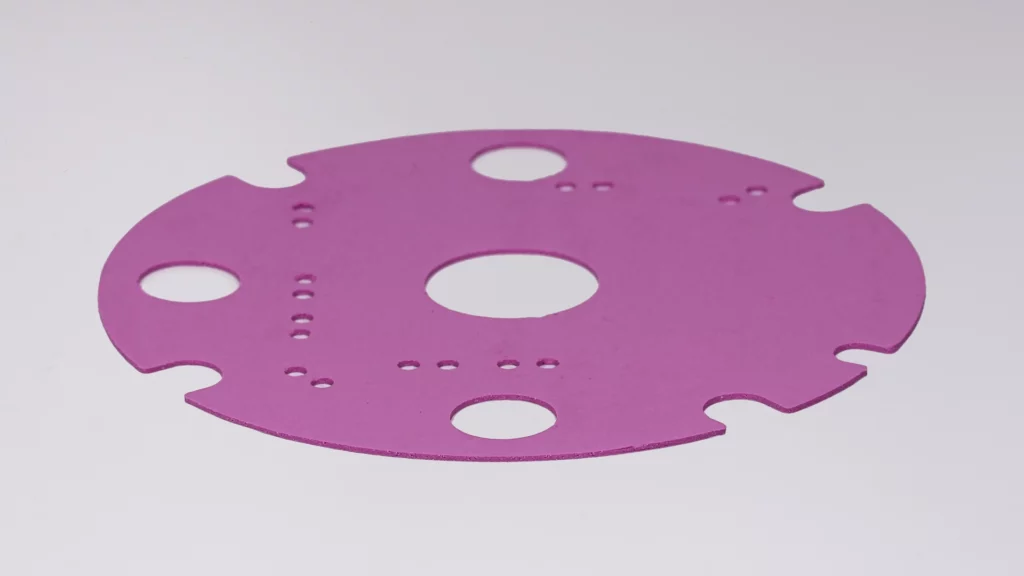

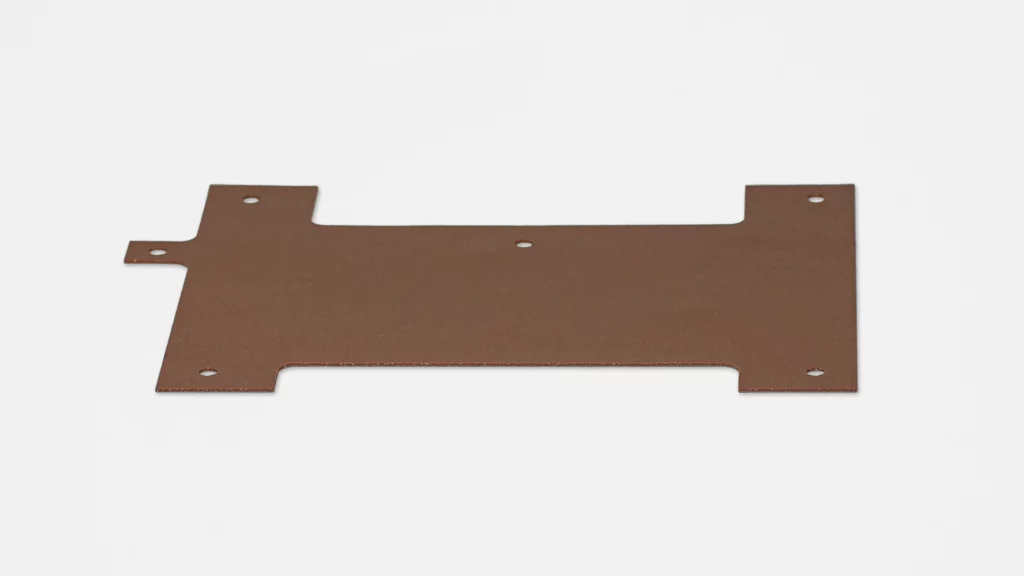

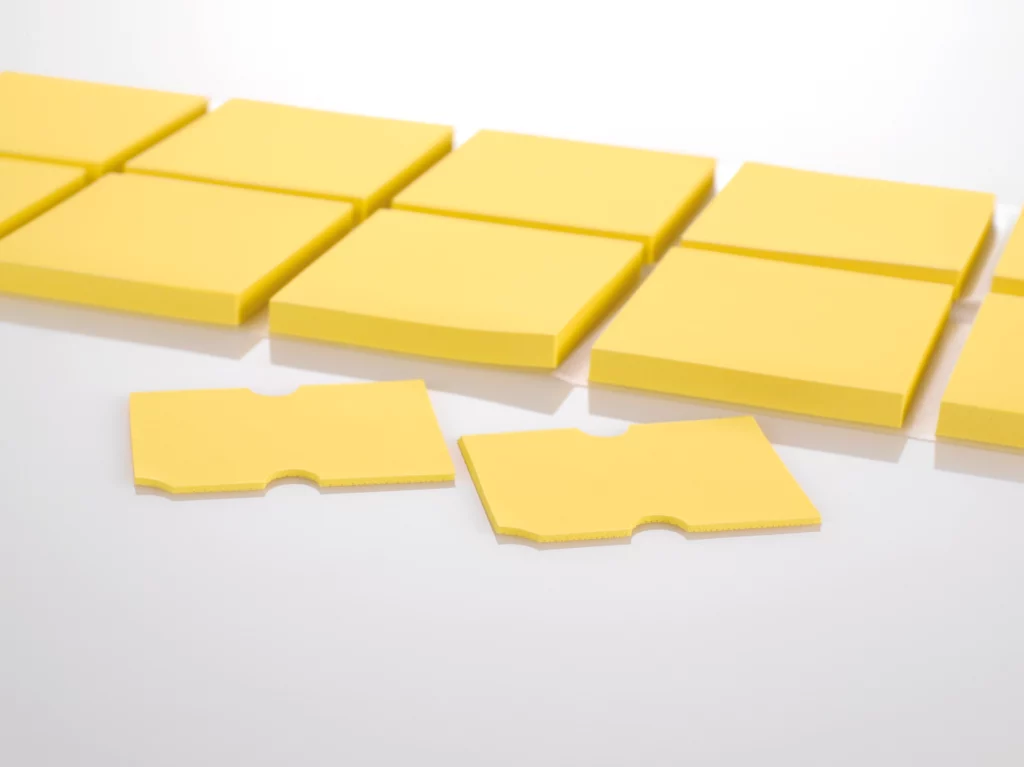

Gap pads (SOFTTHERM® films) are highly thermally conductive and electrically insulating elastomers based on silicone or polyurethane. Their softness and elasticity make them ideal for compensating unevenness and air gaps between electronic components and heat sinks, thus enabling efficient heat transfer. In addition to different thermal conductivity and insulation classes, the gap pads differ in their feel. Two-layer gap pads, for an additional electrical protective layer, or special coatings (e.g. adhesives) are also possible. Depending on customer requirements, gap pads can be produced in different layer thicknesses (0.5 mm to 5.0 mm) and in different contours and dimensions according to drawings.

Key Facts

to the Gap Pads from Kerafol®

- Thermally conductive and electrically insulating

- Soft and elastic

- Used for high component tolerances and gap dimensions in the range from 0.5 to 5.0 mm

- Different polymer bases possible, silicone-containing and silicone-free

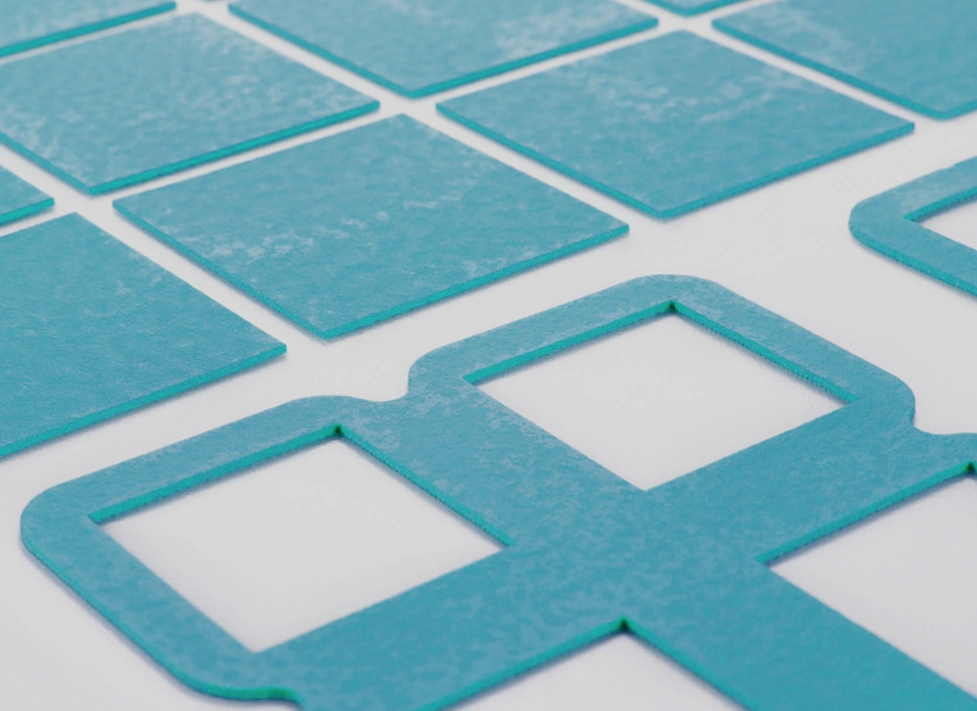

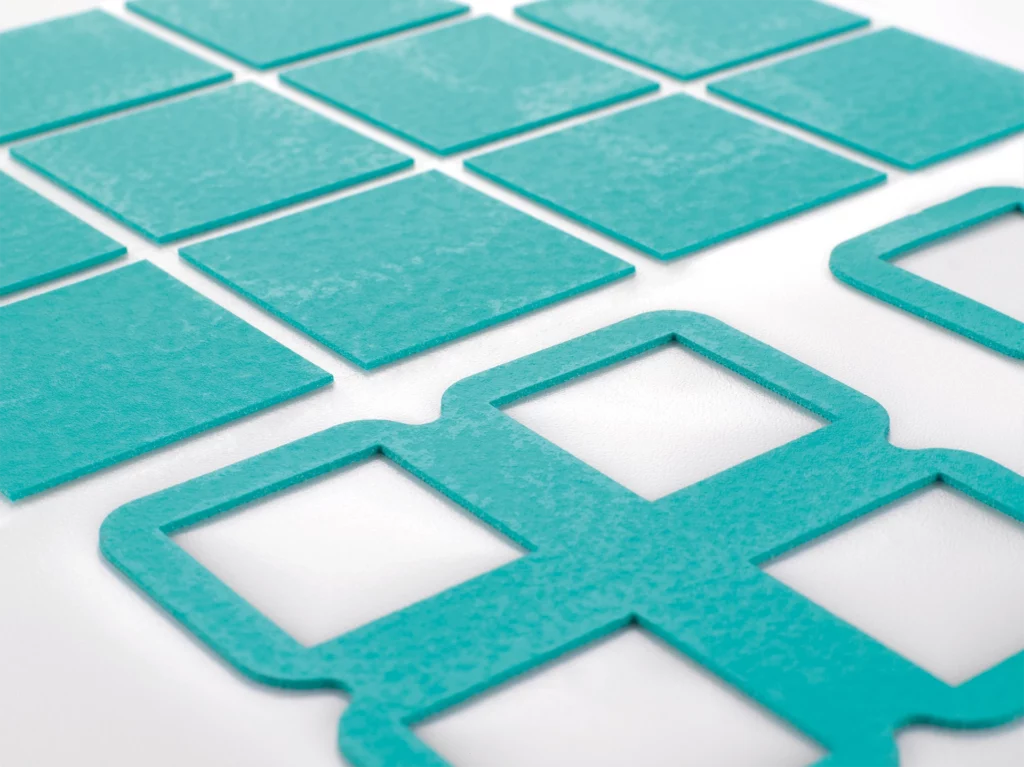

- Available as a standard sheet and as a specific cut to size

- Easy handling and good mechanical strength

How are the Gap Pads applied?

Application

Gap pads (SOFTTHERM® films) from KERAFOL® are available as standard in a sheet size of 450 x 250 mm.

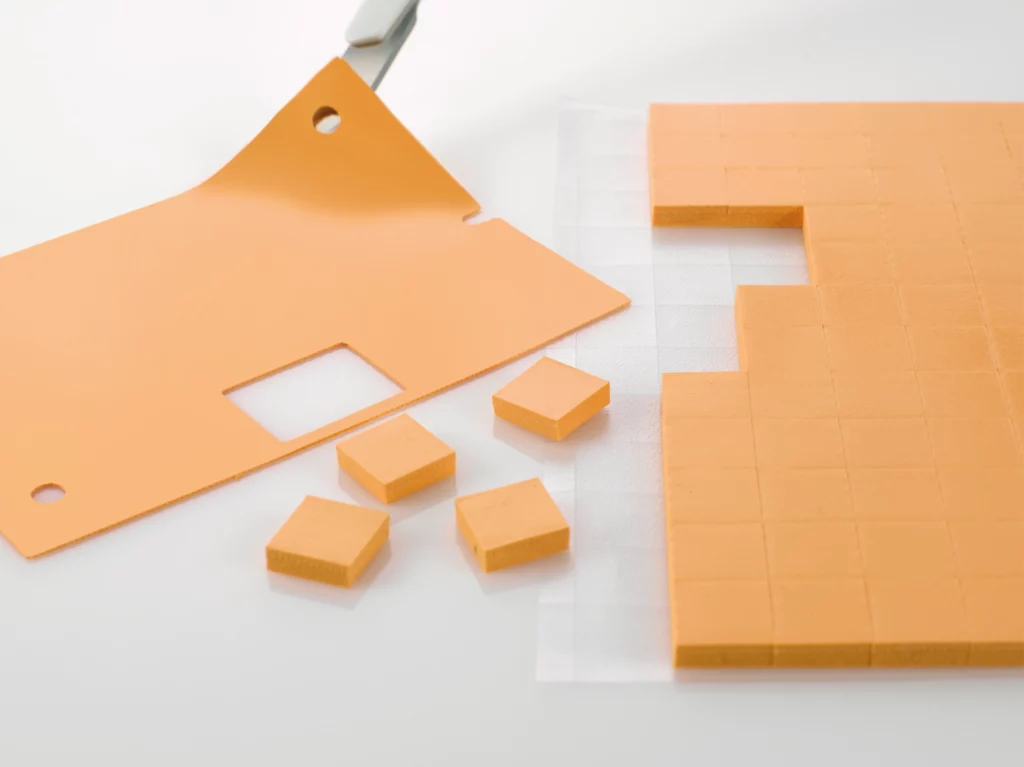

In addition, KERAFOL® also offers pads cut to size, which can be separated according to customer requirements using various cutting and punching systems.

The systems required for this are selected on the basis of years of experience according to the application and quantity.

There are also various options for the delivery form.

Punching residues can be removed on request and various cover films can be used.

Cover and carrier films are used to protect the gap pad from dust and dirt.

These must be removed on site at the customer’s premises immediately before the pad is applied to the electronic component or heat sink.

The gap pad can be easily removed from the carrier film, which simplifies the manual application step.

To facilitate and ensure positioning, most gap pads are slightly self-adhesive, which prevents them from slipping after application.

In the case of fully automated application, so-called “pick and place systems” can be used.

Further information on processing and separation techniques can be found in the Kerafol service section.

Advantages

of the Gap Pads from Kerafol®

- Wide range of products for different requirement profiles

- High heat and long-term resistance

- Wide range of thermal conductivities (up to 6.0 W/mK) and layer thicknesses (up to 5.0 mm)

- High electrical insulation

- Due to the softness of the material, large component unevenness can be compensated for

- Easy handling and good mechanical strength

- High availability

- 100% Made in Germany

Delimitation

to other products

Compared to thermally conductive films, gap pads are softer (Shore 00 instead of Shore A range) and can compensate for larger component tolerances.

While heat conducting foils are produced in the range of 0.1 mm to 0.5 mm, gap pads have common layer thicknesses of 0.5 mm to 5.0 mm. Gap pads have a major advantage over gap filler liquids, particularly when it comes to handling, as it is much quicker and easier to process precisely fitting components than is the case with liquid materials.

Comparison

Gap pads from Kerafol®

Applications

from Gap Pads

- In many power electronics applications and many other electronic assemblies

- Batteries, busbars

- For high component tolerances / large gap dimensions