Thermally conductive adhesive

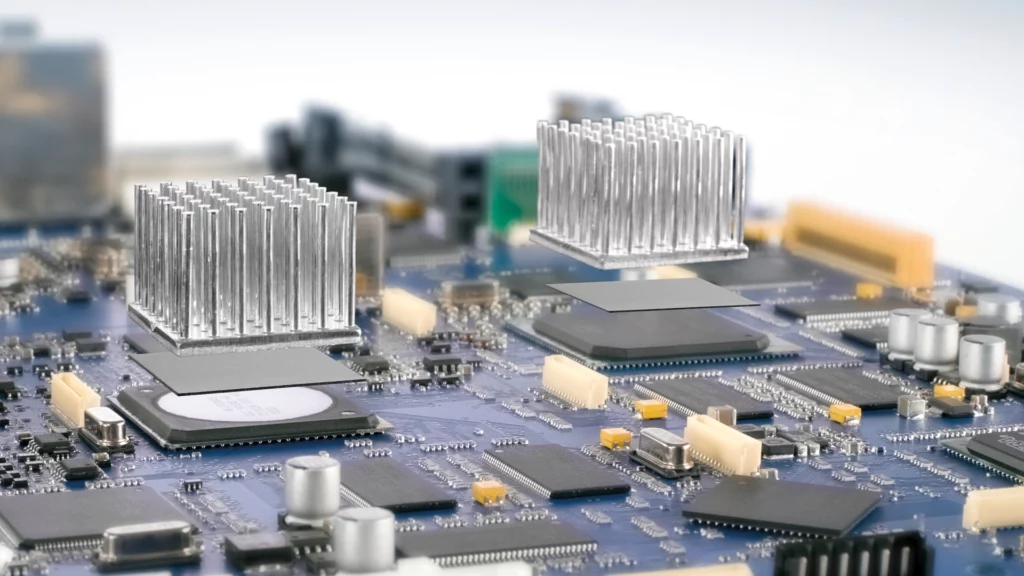

The constantly increasing technical demands on electrical and electronic assemblies lead to major challenges in the area of thermal management. Due to the miniaturization of components and the higher performance of devices, the component temperature would increase significantly without countermeasures, which can lead to the failure of the entire assembly. In order to increase the longevity of electronic components, the heat must therefore be conducted from the heat source (electronics) to the heat sink (e.g. heat sink). Thermally conductive and electrically insulating intermediate layer materials, so-called Thermal Interface Materials (TIMs), are used for this purpose. KERAFOL® has developed effective, uncomplicated and cost-effective solutions in this area with the KERATHERM® and KERAMOLD® product ranges. Thermal Grease is a product group that is also well-known in the consumer sector.

What are thermally conductive adhesives?

an explanation

Key Facts

the thermally conductive adhesive from Kerafol®

- High adhesive strength

- Easy handling

- Low thermal resistance

- Different polymer bases possible, silicone-containing and silicone-free

- Low layer thicknesses possible

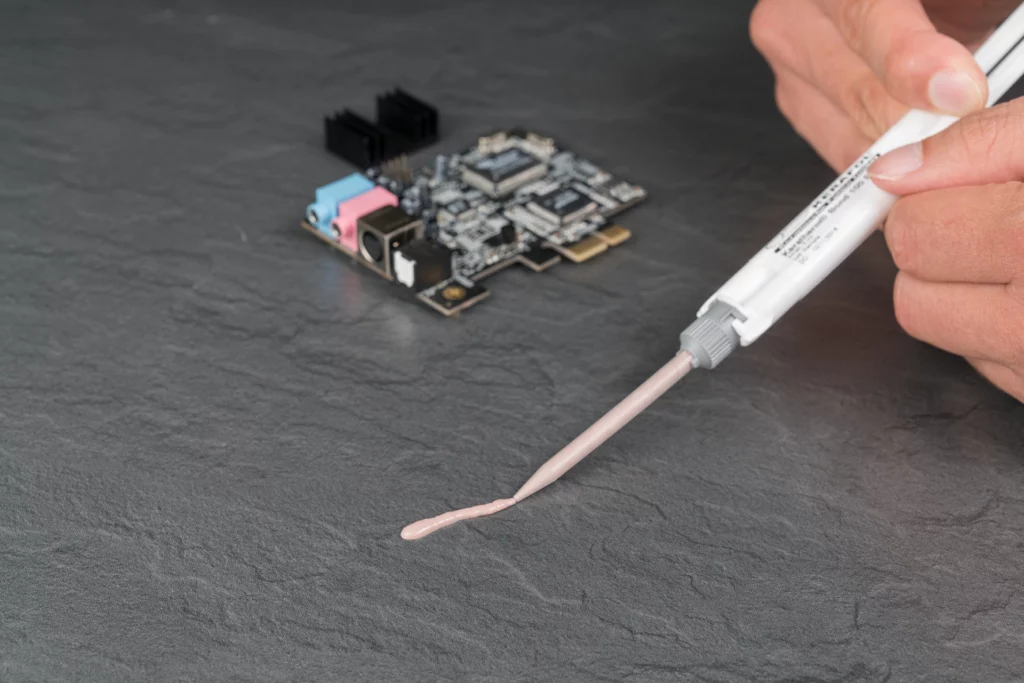

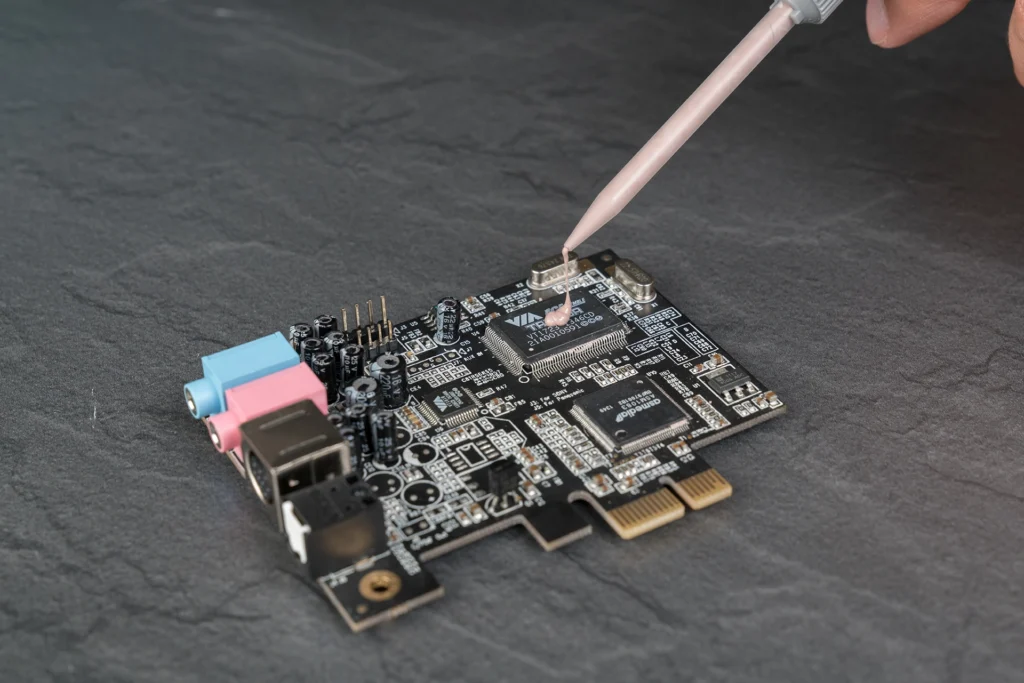

How are the heat-conducting adhesives processed?

Application

- Double cartridges 400 ml

- Hobbocks up to 34.5 kg

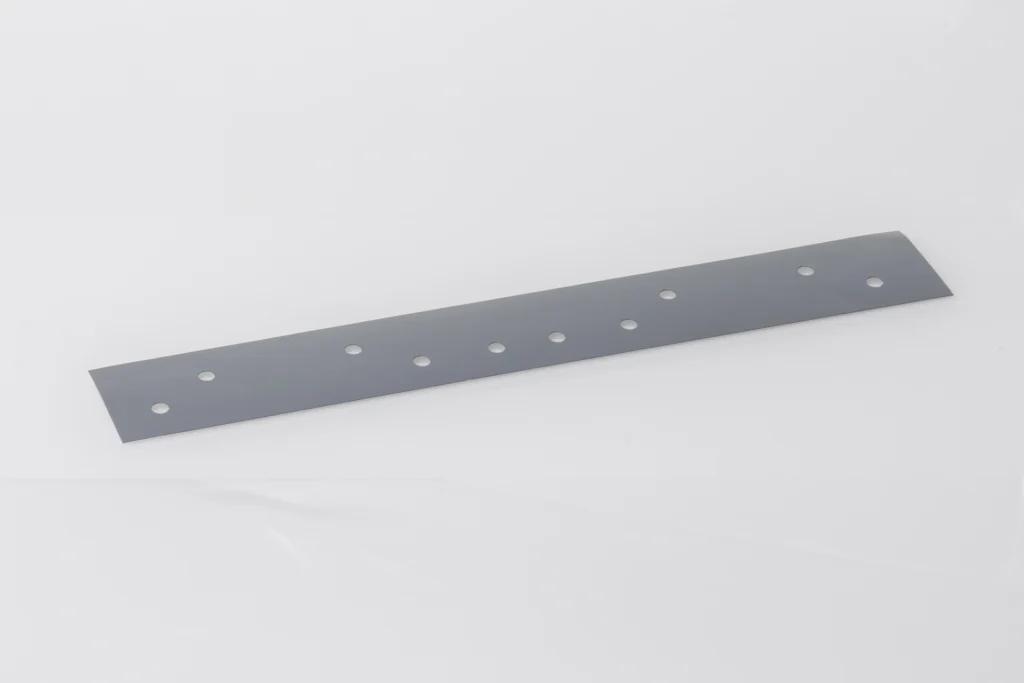

- Punched parts

- Roll goods

In addition to manual application, the liquid 2-component adhesives can also be applied using dispensing systems.

Die-cut parts can be applied either manually or using a “pick & place” system.

Advantages

of the thermally conductive adhesive from Kerafol®

- Good thermal conductivity with high adhesive strength

- Good long-term durability, high softness to compensate for mechanical loads such as vibrations

- Low layer thicknesses possible

- 1:1 mixing ratio and curing at room temperature for the 2-component adhesives

- Easy handling and various application options

- Different polymer bases possible, silicone-containing and silicone-free

- High availability

- 100% Made in Germany

Delimitation

to other products

In contrast to the gap filler liquids, the 2-component adhesive is also a system that cures at room temperature, but the adhesive has a reliably high adhesive strength and the gap filler only has good adhesion.

If components such as battery cells are to be installed completely without additional fixation, a gap filler is no longer sufficient and a thermally conductive adhesive is used.

This saves process time and material, making it an efficient concept.

Comparison

Thermally conductive adhesive from Kerafol®

Applications

of thermally conductive adhesives

- Batteries

- For small component tolerances

- Sensors

- CPUs

- LEDs